All products, no matter their value or level of care, are not immune to imperfection. This applies to metal roofing as well.

Despite the various factors that can impact the performance of a metal roofing system, unexpected events beyond human control can still occur. It’s worth noting that metal roofing generally has fewer long-term issues compared to asphalt shingles or concrete tiles.

At 50 North Roofing, we believe it’s crucial to inform consumers about the potential common issues that may arise with a metal roof. In this article, we will cover:

There are several common issues that can arise with a metal roof, including potential remedies and preventative measures to consider. It’s important to keep these in mind in order to avoid potential problems.

Top 8 Most Common Metal Roofing Problems

#1: Oil Canning

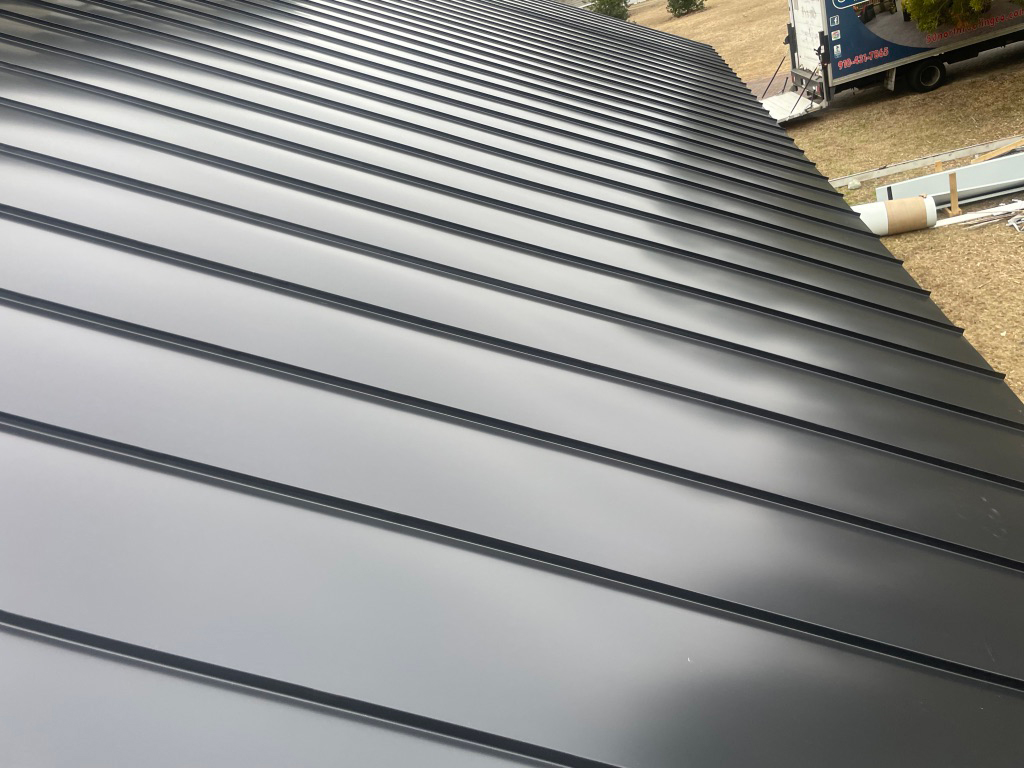

Oil canning, also known as elastic buckling or stress wrinkling, can cause visible waviness in the flat areas of metal roofing and metal wall panels. This phenomenon can occur in steel, aluminum, zinc, or copper panels.

Oil canning is a common characteristic found in nearly all metal roofs and walls. It occurs when the metal on a standing seam system is over-stressed and unable to hold a flat form, resulting in visible waves.

This issue is a popular topic in the metal roofing industry due to its difficulty to define and measure. There are several reasons for oil canning, including:

Over-production, frequent stress during coil slitting, inadequate space for thermal expansion, changes to the structure’s form, and improper usage, handling, and storage by installers can all lead to issues like oil canning. It’s important for contractors to always follow industry-standard manufacturer installation details.

In order to avoid oil canning in metal roofing and siding panels, it’s important to be mindful of factors such as over-production, frequent stress during coil slitting and rollforming, inadequate space for thermal expanding and contracting, changes to the structure’s original form, and improper usage, handling, and storage. Following the manufacturer’s installation details is crucial to minimize these risks.

Fortunately, there are methods available to decrease the chances of oil canning, such as:

When purchasing metal for your roof, consider selecting a thicker gauge to ensure durability. Additionally, utilizing a rib roller profile can help break up the flat space on a panel.

Opting for a low-gloss or matte finish can reduce reflectivity and minimize the visibility of oil canning. It’s also recommended to buy tension-leveled (stretched) metal, as this type of coil is already stretched beyond the point of return to its original state. When installing the roof, make sure to place it over a flat “in-place” roof deck. Most importantly, hire a skilled and experienced installer who is knowledgeable about preventing oil canning.

#2: Leaking

It’s important to acknowledge that nobody wants a leaky roof. Not only can it be costly to repair, but it can also cause damage to other important items in your home or building. While some metal roof leaks are beyond our control, others may be the result of human error.

Common causes of a leaking roof include uncontrollable triggering events such as severe weather, aging materials, and improper installation.

Adverse weather conditions such as driving rain, heavy or melting snow, ice damming from consistent freezing and thawing, strong winds, and structural damage can cause various issues.

Unfortunately, there are situations in which a leak can occur due to mistakes made during the installation process.

The cause of leaks in a standing seam metal roof can often be attributed to failed fasteners, seams, or flashing. These components can allow water to enter at open spots if they are too tight, too loose, off-center, formed incorrectly, or improperly installed.

Flashing, in particular, is a common source of leaks in standing seam metal roofs, as it requires precise installation and sealants to prevent moisture from entering at joints or additions on the roof.

Failed sealant or butyl tape can lead to leaks in a metal roof. It’s important to ask your contractor about the specific details they plan to use during the installation.

Make sure they align with the manufacturer’s recommendations for a weather-tight warranty. This will ensure the best protection for your home or building. It’s important to stay involved in the process from the beginning to ensure the correct details are being used.

It is important to select a reputable contractor with a strong history of quality installations to minimize the risk of leaks occurring.

#3: Scuffing & Scratching

Metal roofing, like any other surface with a paint system, is susceptible to scratching or scuffing. However, most metal coil manufacturers take extra precautions to prevent scratching during the slitting process, recoiling, and transportation to the buyer.

Furthermore, it is common for contractors and installers to carefully handle coils and panels during the rollforming and installation process. However, there is a chance that improper handling by one or more parties could result in surface-level damage. This risk exists when:

The metal may be at risk of rubbing together and losing its coating if it is improperly coiled or recoiled. It is important to use edge guards to protect sheet edges during shipping and to handle coils with proper lifting devices. In addition, it is crucial to ensure that the rollforming machine is functioning properly to avoid unintentional scraping of the coil against machine parts.

Furthermore, extra care should be taken to prevent tools or other items from rubbing against or being dropped on panels. Once installed, panels should be walked on with caution to avoid scuffing, especially at heavy traffic spots. Special handling and care are required for acrylic-coated Galvalume to prevent scuffing.

If you see a scratch or scuff on a metal panel, particularly one that goes all the way to the metal substrate, it’s important to notify the manufacturer or contractor.

Most scratches can be easily repaired with a matching paint or touch-up pen. However, if there is a deep gouge that reaches the core of the steel, the affected metal panel or flashing should be replaced without delay.

#4: Corrosion

Metal roofing is a popular choice for its long-lasting durability, with many people opting for this option as it can withstand corrosion and degradation for over 60 years. Manufacturers and contractors can assist in selecting the most suitable metal material that will effectively withstand corrosion in your specific environment, making it the last roof you’ll ever need to purchase.

Metal roofs are typically equipped with protective paint systems or coatings designed to prevent corrosion. However, certain special circumstances may still arise.

The potential for underside corrosion exists when the metal panel is not properly coated, allowing water molecules to become trapped between the panel and the insulation or underlayment.

This can lead to weakening of the metal if it is not adequately protected. Additionally, using a granulated underlayment or installing directly over a shingle roof can cause scratching of the protective backside coating, ultimately leading to the failure of the metal roof system from the inside out.

Living near the coast can pose challenges for homes and buildings due to saltwater corrosion. It’s important to be aware that substrates and paint warranties may not apply in these environments. While some metals like aluminum and zinc are more resistant to saltwater, there is still no guarantee of longevity compared to non-coastal areas. Be sure to carefully review warranty and product specifications to determine if your location may be susceptible to premature corrosion.

Different types of metals can react negatively when they are in contact with each other, leading to premature corrosion. This is a common problem that we will discuss further in the next section.

When installing a steel roof, it’s important to consider the potential for edge creep, which is minimal rusting that can occur at cut edges.

To minimize this, contractors can use lap flashing, hem exposed edges, or use a paint pen on visible cut edges. Additionally, many standing seam metal roofs have folds or hemmed edges that conceal the cut edge of the metal, providing an extra layer of protection.

Corrosion is inevitable over time for roofs, but understanding the various metal types, paint systems, and environmental factors can help determine when it may occur, whether it’s early on or after 50 years.

#5: Dissimilar Metals & Materials

When different metals are combined on a metal roof system, it can cause interactions that result in early degradation, staining, and potential system failure. For instance, Galvalume® roofing is most effective when it is not in contact with certain materials like copper, bricks, treated lumber, iron, and concrete. If Galvalume comes into contact with one of these materials and is then exposed to an electrolyte, such as water, it will lead to galvanic corrosion of the anode, ultimately causing corrosion.

It’s important to have a conversation with your contractor about the materials that will be in contact with your metal roof to ensure that they won’t cause any corrosion. Alternatively, you can research metals that are more prone to galvanic reactions, which can lead to corrosion. Be on the lookout for potential products and their metal roofing materials that could lead to poor interactions.

Panels

Gutters

Fasteners

Rivets

Trim

Chimneys

Fascia

Drip edges

Siding/wall materials

#6: Chalking & Fading

Chalking and fading can be common issues with painted or coated metal panels due to UV exposure causing the paint resin to break down, resulting in a whitish residue on the surface.

Fading occurs when the pigment in the paint on a metal substrate breaks down due to various factors such as UV rays, water, pollution, and chemicals. This breakdown results in a change in color. Uneven fading may also occur because not every panel on a roof is always evenly exposed to the sun and other substances.

Chalking and fading will happen no matter where you live.

The extent of chalk and fade on a roof is determined by the environment and substances it is exposed to. Fortunately, many trusted manufacturers provide paint warranties that specifically cover chalking and fading beyond a certain level over a set period of time, with these details clearly outlined in the warranty.

#7: Other Installation Error

In the next section, we will provide strategies for avoiding installation errors such as missing parts or accessories, loose screws, and poorly attached flashing. One way to prevent these issues is by selecting a qualified installer.

Important Considerations to Help Minimize Metal Roofing Problems

After learning about the seven most common issues that may impact a metal roof, it’s important to consider a few key factors before and after making a purchase.

Choose the Right Metal Roofing Contractor

It’s important to note that there are contractors and installers who may lack the necessary experience or qualifications to properly install metal roofing. This is why it is crucial to carefully select the right contractor. To ensure that a contractor can meet the highest standards, it is recommended to verify the following:

They have met all necessary licensing and insurance requirements and are in compliance with the building department. They have a track record of successfully installing metal roofing. They are readily available to assist and can address any concerns you may have. They offer thorough information about the products and installation procedures. They come highly recommended by previous clients such as family, friends, and neighbors who have utilized their services.

If you’re unable to find someone with a metal roof, you can seek out reviews and recommendations on referral sites like Google or the Better Business Bureau. Alternatively, you can reach out to the Metal Roofing Alliance to inquire about referrals in your area.

Know Manufacturers That Make Quality Metal Products

Purchasing metal roofing materials from a reputable company that thoroughly tests its products and offers warranties is essential for minimizing potential issues. It is also important to ensure that the manufacturer’s products meet the standards set by government and industry governing bodies.

Know Your Roof & its Environment

When considering the purchase of a new metal roof, it’s important to be aware of the various design considerations that could impact the panel profile needed and the most suitable material for your specific environment.

The angle of the roof, also known as the pitch or slope, is an important factor to consider when choosing a standing seam metal roofing system. For roofs with a low slope of 3:12 or less, a double locked mechanical system is recommended. On the other hand, for roofs with a steep slope of 3:12 or greater, snap-lock systems with a clip are the preferred choice.

It’s important to select the right system based on the specific pitch of your roof to ensure proper installation and performance.

Also, it’s important as well, to check the manufacturer’s minimum slope requirements before installation.

The square footage of your roof will determine the number of flashing points, such as valleys, chimneys, vent pipes, skylights, etc. These are areas on your roof that may collect water, moisture, or debris, as well as parts that are constantly shaded or exposed to the sun. Additionally, existing leaks or other issues may or may not be fixed by a roof replacement.

#8 Noise

Metal roofs are known for being louder than other roofing materials, especially during heavy rain, hail, or when branches fall on the roof. This is because metal roofs are typically harder and more rigid, which amplifies the sound of impact. The design and underlayment used can also affect noise levels, with a solid sheathing or insulation layer helping to dampen sound and reduce the noise transmitted into the building.

Do Your Research on Everything Metal Roofing

It is important to conduct thorough research before and after purchasing a metal roof. This will help you understand potential issues that may arise and who to contact if they do. By being well-informed, you can make educated decisions based on the knowledge you have gained.

Final Thoughts on Common Metal Roofing Problems

It’s impossible to predict the future, but being aware of potential issues with a metal roof system can give you an advantage when making a purchase. It’s important to be prepared, but keep in mind that not all of the problems we mentioned may actually occur. Just remember:

When selecting a metal roofing contractor or installer, it’s important to ask for referrals. It’s not advisable to attempt to fix roofing problems without professional assistance. Be sure to check your warranty and understand what could be considered a legitimate claim. It’s also a good idea to do routine checks to make sure there are no compromises in the roofing structure. Stay informed by asking questions and remaining educated about potential roofing issues.

We at 50 North roofing are dedicated to providing you with the necessary information and high-quality products to ensure the longevity of your metal roof. Reach out to us today to consult with our experienced and knowledgeable metal roofing experts.