Pros and Cons of 24 Gauge vs. 26 Gauge Metal Roofing: Which One Should You Choose?

When choosing metal roofing, you will need to decide on the metal gauge that best suits your needs.

Before you begin to concentrate on the gauge, it’s important to have already made decisions about the type of metal roofing you plan to purchase.

Panel Profile

Paint System

Metal Roofing Color

We recommend that you prioritize choosing your metal roofing panels before making a decision on the gauge.

One important factor to consider when choosing gauge is that it may already be determined for you based on other options you select.

50 North Roofing has been specializing in metal roofing installation for more than 20 years, assisting numerous customers in selecting the most suitable metal panels for their construction projects.

Through our extensive experience, we have observed that one crucial decision that is often overlooked is the selection of the appropriate gauge metal to use.

Metal roofing comes in various thicknesses, but the most commonly used gauges for residential and commercial applications are 24-gauge and 26-gauge.

While there is no standard gauge for metal roofing, these two thicknesses are preferred for their durability and strength. It’s important to consider the specific needs of your project when choosing between the two gauges, as there are times when one may be a better choice than the other.

In this article, we will cover how to select between 24 gauge and 26 gauge metal based on various factors, including the type of roofing panels, to help you make an informed decision about which is most suitable for your needs.

How Does Metal Thickness Work?

Metal gauge is a standard measure of the thickness of metal, and it is denoted by a number. As the number goes up, the thickness of the metal goes down.

Metal roofing is available in various gauge types, with 22, 24, 26, and 29 being the most common options. It’s important to note that the lower the gauge number, the thicker the metal. For example, 22 gauge is thicker than 29 gauge.

Standing Seam vs Corrugated Metal Roofing

Before determining the gauge of the panel, the first decision that needs to be made is to determine which gauges are even available, as this decision will have a direct impact on the available options.

What Gauge Is Standing Seam Metal Roofing?

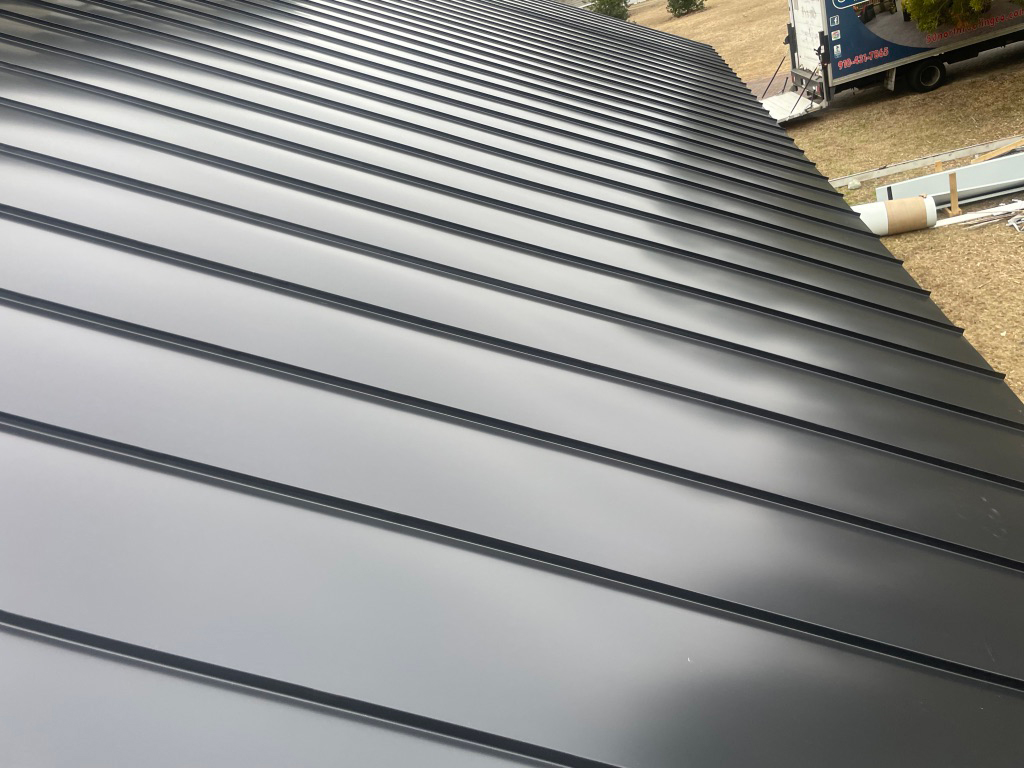

Standing seam roofs are designed with the best features, such as concealed fasteners, a PVDF paint finish, and heavy gauge steel. When you purchase a standing seam roof, you are investing in a panel that is built to last a lifetime, typically in 24 gauge.

Purchasing an expensive roof system and then manufacturing it in a 26 gauge or 29 gauge metal would not be a wise decision. While it may save a small amount on the overall cost of the roof, using a lighter gauge metal will reduce the longevity of the panel.

Consider using 22 gauge standing seam metal roofing to reduce the likelihood of oil canning, but be aware that it will come with a 20% increase in cost. Typically, anything heavier than 24 gauge is rarely needed.

Corrugated Metal Roofing Thickness

The gauge for an exposed fastener metal roofing system is not standardized. The correct gauge is primarily determined by whether the panel is installed on a solid wood substrate or spanning from support to support.

Residential Metal Roofing Over A Solid Wood Substrate

The most common type of residential metal roofing installation involves a solid wood substrate and roofing underlayment, with the panel being installed on top. This method does not require the panel to support any weight.

Both 24 and 26 gauge are suitable for this type of metal roofing installation. The advantages and disadvantages of each will be further explored in this article.

Metal Roofing Spanning From Support To Support

This roofing system may feature either metal purlins or wood beams, spaced at varying distances, to support the panels and any loads they may need to carry, such as snow or wind uplift, as well as foot traffic.

24 gauge metal roofing can span longer distances and support heavier loads compared to 26 gauge. However, the specific requirements of each job can vary, and load charts and uplift charts are used to determine which metal roofing gauge will best meet the load requirements.

24 Gauge Vs. 26 Gauge Metal Roofing Thickness

The gauge numbers on steel indicate their thickness, with each gauge having a specific range. For example, when comparing 24-gauge and 26-gauge steel, there is approximately a 30% difference in thickness between the two.

How Much Metal Roofing Panels Weight?

The weight of a roofing panel is directly related to its gauge. For example, a 24-gauge panel typically weighs about 30% more than a 26-gauge panel. It’s important to note that the weight of each gauge can vary within a range, just like the thickness.

When Should You Use A Thicker Metal Roof Panel?

Both 24 gauge and 26 gauge panels offer the durability of metal roofing. They are fire-resistant, low maintenance, and protect against corrosion. However, the thickness of the panel does impact its durability, making 24 gauge metal roofing a better choice for harsher climates.

Why Is 24 Gauge Metal Roofing Better For Climates With Snow?

When installing a metal roof in a harsh climate with snow, heavy winds, and hail, it is recommended to use a thicker gauge. A 24 gauge metal roof offers greater strength, better impact resistance to hail, and can handle higher winds and heavier snow loads compared to a 26 gauge metal roof.

Metal Panel Paint Options Based On Gauge

Remember, before choosing a paint finish for your project, it’s important to consider the differences between PVDF and SMP. PVDF paint systems are known for fading at a slower rate than SMP panels, which is especially crucial for bright and vibrant colors. This means that color fade will be less noticeable on lighter colors like white or tan, compared to more vibrant colors like green or red.

PVDF Paint System And Gauge

When considering a PVDF paint system for your metal roofing, it’s important to note that it is typically only available for a minimum of 24 gauge metal. In most cases, 26 gauge metal roofing will not be an option.

SMP Paint System And Gauge

SMP painted panels are typically available in 26 gauge and have a limited color selection. If you are looking for 24 gauge metal roofing with an SMP paint finish, you may find that the color options are also limited.

Heavier Gauge Metal Panels Panel Can Decrease Oil Canning

It’s difficult for someone to determine the gauge of the metal just by looking at your roof. The appearance of the panels isn’t noticeably different between gauges, but the composition of the panels could result in some aesthetic variations.

Oil canning is a major issue for metal roofing, as it causes unsightly wrinkles on the panels. This can be caused by a variety of factors, such as over-tightened screws during installation or the natural expansion and contraction of metal.

Using a thicker gauge of metal that is less malleable can help reduce the visibility of oil canning, as thicker panels are generally stronger and less prone to this issue.

The 24-gauge metal roof is less prone to oil canning and is more resistant to dents and punctures from hail or debris than the 26-gauge roof due to its increased thickness.

Metal Roofing Prices By Gauge

As the thickness of the panel increases, so does the cost. For example, a 24 gauge metal roofing will be more expensive than a 26 gauge.

24 Gauge Metal Roofing Prices

24 gauge metal roofing prices range anywhere from $1.20 to $5.50 per sq. ft. The price depends on the type of panel and finish you choose. Below is a price breakdown of each category.

The cost of 24 gauge corrugated metal roofing varies depending on the type of finish. Galvalume or galvanized finishes typically range from $1 to $1.50 per square foot. PVDF painted corrugated metal is priced between $1.50 and $2 per square foot, while specialty painted finishes can cost between $2.50 and $3.50 per square foot.

The cost of a 24 gauge standing seam metal roof can vary depending on the type of material and finish. Galvalume or galvanized options typically range from $1.50 to $2.50 per square foot. If you opt for a PVDF painted standing seam, you can expect to pay between $2 and $4 per square foot. For specialty painted finishes, the cost can be higher, ranging from $3 to $5 per square foot.

The cost of 26 gauge metal roofing typically ranges from $.75 to $1.50 per square foot, with variations based on the finish and type of panel.

The cost of 26 gauge corrugated metal varies depending on the type of material. Galvalume or galvanized corrugated metal typically costs between 75 cents and $1.25 per square foot, while SMP painted corrugated metal usually ranges from $1 to $1.50 per square foot.

Should You Use 24 Gauge Or 26 Gauge Metal Panels?

Thicker panels are generally more durable, but they also come with a higher price tag and may not be necessary for every home. Here are some general guidelines for when to use each type of panel:

Choose 24 Gauge Metal Panels If:

In a climate with extreme weather conditions such as hail, strong winds, and heavy snow, a thicker, more durable panel is necessary for your roof installation. This will ensure greater resistance to oil canning and dents from hail storms, and the metal roofing will require a heavier gauge thickness to span from support to support. For your project, you will be purchasing a standing seam metal roof and using a PVDF paint system.

You Should Use 26 Gauge Metal Panels If:

When considering your options for roofing, it’s important to keep cost in mind. If you’re in a mild climate without frequent snow, hail, or storms, you may want to consider an exposed fastener metal roofing panel with an SMP paint system. This can be a more affordable choice for commercial or agricultural jobs.

Choosing The Right Metal Roofing Color

We discussed the three important decisions to make before selecting the best gauge metal roofing. We covered all of them except for choosing a metal roofing color, which is an exciting yet challenging decision. Once you choose your color, it’s important to note that metal roofing is difficult to repaint, so it’s a decision that requires careful consideration.