Why Aluminum Roofing is a Smart Investment for Long-Term Durability

Some metal roofs may vary in quality and durability, and this is especially true for aluminum roofing. Despite being the lightest of all roofing materials, aluminum is still able to match the strength of thicker metals and in some cases, even surpass them.

Customers often ask about the different types of metal roofing and which one would be best for their roof. However, the most suitable type of metal roofing depends on the specific circumstances of each individual situation.

The type of metal used for roofing is dependent on factors such as the home’s location and its roof pitch. While aluminum offers numerous benefits for roofing, it may not be suitable for every situation.

This article discusses the advantages and disadvantages of aluminum roofing and provides guidance on when it is most suitable for use.

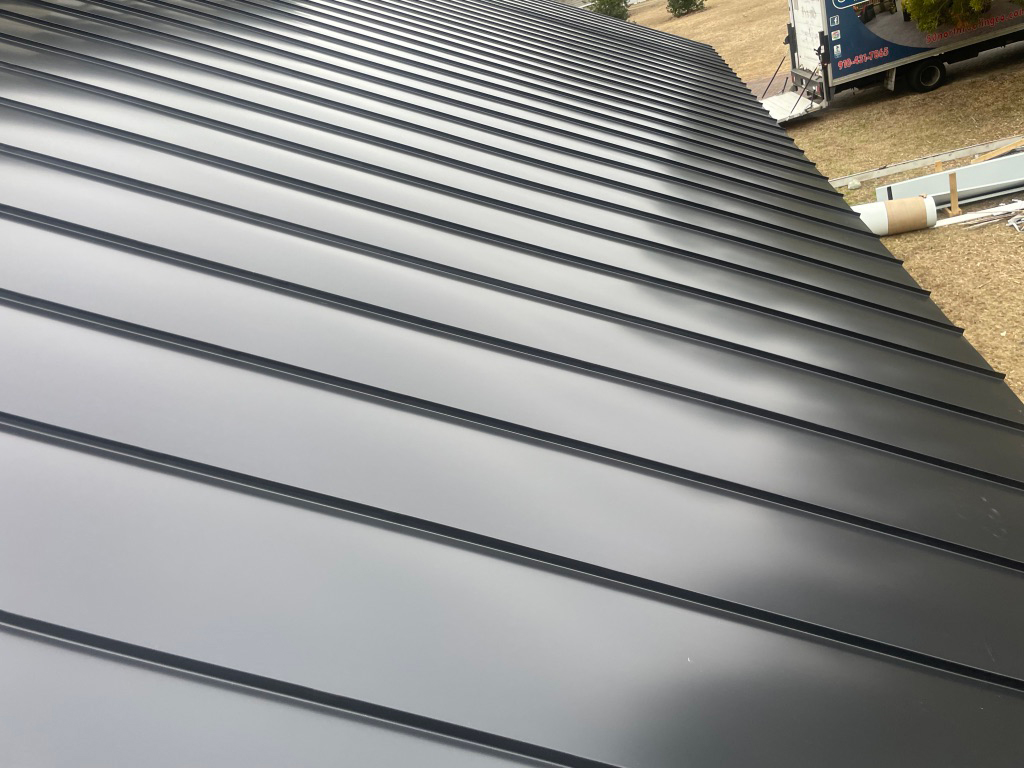

What Is Aluminum Roofing?

Aluminum roofing is a lightweight and durable roofing system made from malleable and corrosion resistant aluminum panels. In fact, aluminum is the most lightweight roofing material available on the market and has a higher strength to weight ratio compared to other types of metals used for roofing.

Aluminum roofing offers low maintenance, durability, and a range of color options. It is commonly used for architectural purposes rather than structural support.

Aluminum roofing falls under the category of metal roofing, so while some may use the terms interchangeably, it’s important to note that aluminum roofing is a specific type within the broader category of metal roofing.

Other types of metal roofing include:

Copper

Zinc

Steel

Throughout this article, we compare aluminum to steel multiple times because they are the two most popular metal roofing choices and are often compared to each other.

Uses for Aluminum Metal Roofing Systems

Let’s discuss the key characteristics and uses of aluminum in metal roofing.

Aluminum sheet and coil products are available in various thicknesses, typically measured in inches in decimal form. The higher the number/decimal, the thicker the aluminum material. The choice of thickness depends on the specific application for which the aluminum will be used.

The most common thickness for residential roofing projects is .032” or .030”, while for commercial roofing projects, .040” is most common. For copings or caps, .050” or .063” thickness is most common.

Aluminum is a versatile material that can be used for roofs, walls, trim, and more in a variety of environments, including coastal areas, hurricane zones, regions with heavy rain or snowfall, and high-temperature locations.

Aluminum is commonly used in a variety of applications, including coastal structures such as hotels, homes, and boathouses; commercial buildings like hospitals and schools; residential projects including single-family homes and condominiums; architectural structures in commercial, governmental, and residential settings; and structural or industrial applications such as warehouses and factories.

Aluminum Roofing Advantages

Corrosion Resistant- Suitable for Coastal Properties

Lightweight

Energy Efficient/ Eco-friendly

Long Lasting

Corrosion Resistant

One of the major benefits of aluminum is its resistance to rust. While it does not rust in the traditional sense, aluminum can still oxidize. It’s important to use a paint system specifically designed for your climate to protect the aluminum from oxidation.

Aluminum is the perfect material for areas with high levels of precipitation and coastal environments. Unlike steel, aluminum is not affected by sea salt spray, making it an ideal choice for these locations.

Lightweight

Aluminum is an extremely lightweight roofing material, weighing as little as 5 lbs per square foot. This not only makes it easier to handle and install, but also reduces the amount of stress placed on your home’s structure compared to heavier materials.

Highly Recyclable

Over the past 20 to 25 years, sustainability has become increasingly important in the construction industry, leading to the rise of metal products.

One of the reasons for this is that metal is almost always recyclable, with aluminum being one of the most reusable and sustainable metals in the world. In fact, approximately 95% of all aluminum roofing systems installed globally are made from previously recycled aluminum materials.

Many architects and building owners choose aluminum for their projects because of its high recyclability and reusability, particularly those seeking to meet LEED certification requirements. LEED is the most widely used building rating system, promoting “healthy, efficient, carbon and cost-saving green buildings.”

Warrantied Product

It is advisable to purchase a roof product with a warranty due to its importance. Fortunately, aluminum metal roofs offer a range of warranty options, such as paint, substrate, and weathertight warranties.

These warranties help safeguard your investment and provide assurance that the roof or wall system will endure. It is important to consult with the manufacturer for specific warranty types and timeframes offered.

Paint warranties are available for aluminum sheets and coils used in coastal applications. For instance, certain aluminum roof manufacturers provide a 25-year PVDF paint warranty for properties along the coast.

Color Options

Aluminum sheet and coil products typically offer similar, if not identical, color options as Galvalume. This means that if your project calls for an aluminum panel system, you won’t have to sacrifice your desired color.

See different color options here: Metal Roofing Colors

Long Lasting

An aluminum roof is a durable choice, with an average lifespan of 50 years, and some roofs lasting beyond 70 years.

Aluminum Roofing Disadvantages

Cost

Aluminum roofing panels typically cost between $7-10 per square foot for materials, which can be up to 20% more than steel roofing.

More Prone To Denting

Aluminum is more susceptible to dents from hail, falling branches, or walking on the roof compared to steel due to its softer nature. Using a thicker gauge aluminum can increase its strength and durability, but it will also come at a higher cost. The lower the gauge, the higher the price.

Requires More Space for Thermal Movement

When installing an Aluminum roof, it’s important for contractors to take into account the thermal movement of the panels.

Aluminum expands and contracts approximately twice as much as steel, so it’s crucial to allow enough room for this movement during installation.

This is especially important when using mechanically seamed panels that are longer than 15-20 feet. To accommodate this, it’s recommended to use expansion clips in accordance with the applicable engineering standards.

Limited flexibility of an aluminum roof can lead to oil canning, heightened noise, and an increase in necessary maintenance for any exposed fasteners.

When Is It Best To Use Aluminum Roofing?

Aluminum roofing is a high-quality metal roofing material that is often more expensive than steel initially, but it offers great benefits when used in specific areas. It is ideal for use in coastal regions where corrosion is a concern, for architectural roofing, and for roofs with a minimum slope of 3:12.

Final Thoughts on Aluminum Metal Roofing

Aluminum is a versatile roofing material suitable for various applications, but it is crucial to understand the appropriate circumstances for its installation.

Just to summarize: Aluminum is a great choice for coastal environments because it doesn’t rust and forms a protective coating when exposed to corrosive conditions. It’s lightweight and easy to handle, and comes with warranty options, including a PVDF paint warranty for coastal areas.

However, it can be more prone to denting, comes at a higher price than steel, and needs adequate space for thermal movement.

At 50 North Roofing, we are committed to providing valuable information and guidance to our customers and potential buyers. We aim to help you make well-informed decisions about the best metal roofing material for your roofing project, whether it’s aluminum or another option.

Regardless of whether you’re a contractor, architect, manufacturer, property owner, or other professional, we are here to collaborate with you in selecting the most suitable material for your metal roofing projects.