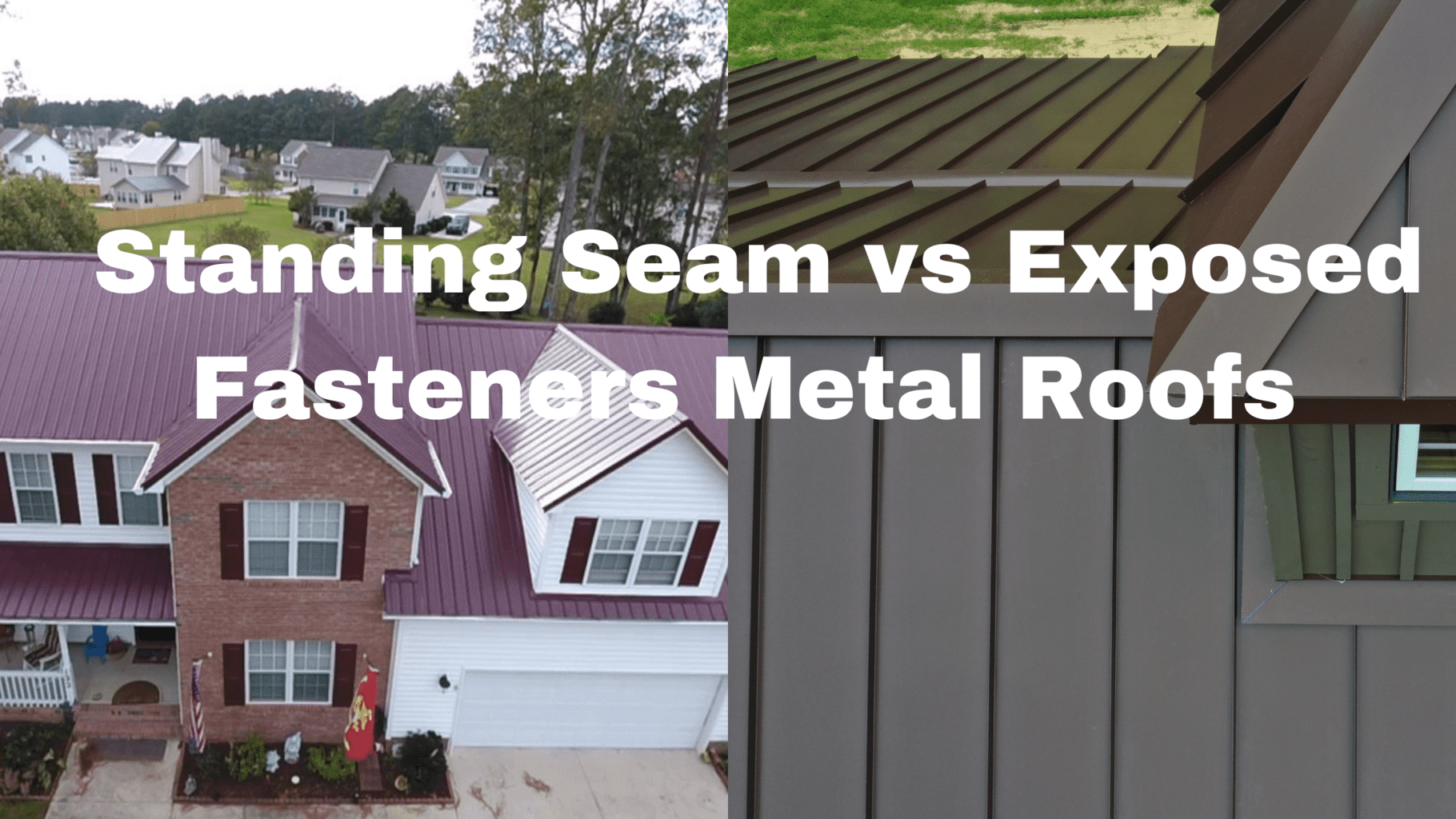

We are going to talk about both standing seam roofing and exposed fastener metal roofing systems. These two types of roofs are used very often, but there are some important differences between them. When it comes time to put a new roof on your home or business, you should definitely consider one of these options.

There are several factors to consider when making this decision. Some of the things you should be aware of include:

Exposed fastener metal roofing system

The exposed metal roofing panel is a roofing system in which the panels are fastened to the structure through the face of metal and directly into the roof deck or framing below. The exposed fastener metal roof is the most common style of metal roofing used for agricultural and residential applications.

Less expensive

When compared to standing seam systems, exposed metal roofing is less expensive. There are many reasons for the low price.

Wider panels available (up to 36”)

More coverage is provided on every panel, fewer panels need to be purchased.

Fewer labor hours are required because the wider panels cover the roof faster.

Metal thickness

The exposed fastener systems generally use metal with a thickness of 29 to 26 gauge, which makes them lighter.

Paint and coatings

Silicone-modified polyester (SMP) paint systems are less expensive than the resin based coating used for standing seam systems, so they are a popular choice for exposed fastening.

More substrate Options

Can be installed over Solid Substrate or on Open Framing.

Less accessories and trim needed

Exposed fastener systems are fastened down to the structure through the metal without any clips. This can save money on the part of the buyer.

The roof systems are usually installed using less accessories and different flashing products. This cuts down on costs and increases the speed of the installation.

Seaming is not required

Hand or mechanical seaming the two panels is not required for exposed fastening systems. Most systems use a lap seam where the edges of each panel overlap the one next to them and are fastened down together at the same time. When compared to standing seam metal roofing, exposed fastener metal roofing is often considered the less labor-intensive option.

Performs relatively well

If the system has been correctly installed for its environment, it will hold up well in the weather. Oil canning is not very common to occur, there aren’t broad flat areas on of the panels between the ribs, which helps reduce the visibility of it. There are many of attachment points to the deck since you can screw down the entire width of the panel. Most exposed fastening systems are not engineered to meet strict industry standards like standing seam metal roofing, meaning how the roof will perform is not verified. Depending on the system being offered and the manufacturer, panel testing can vary. It is important to make sure that the product you are buying has the proper testing for the building type and location.

More contractors have the skills to install it

Most contractors who install exposed fasteners metal roofing have the necessary knowledge, experience, and tools to offer exposed fastener systems to their customers since it is easier to install. It doesn’t require the same level of craftsmanship as a standing seam metal roofing because it requires skill as far as lining up the panels, correctly spacing the fasteners, and cutting the panels to match the roof’s geometry.

There is more chance for do-it-yourself projects

Because it is easier to install, there’s more of an opportunity for homeowners to perform the installation themselves as a DIY project. Standing seam metal roofing always recommends that you hire a knowledgeable, experienced, and trusted metal roofing installer.

Many big-box stores sell panels

When using exposed fastener profiles (like PBR, R-panel, or 5V) you can vary the prices, options, colors, sizes, and other factors to suit your needs. This allows you to provide more flexibility when it comes to purchasing your metal, very often it is available at some big stores. These include the manufacturer, from a regional panel supplier, from a local hardware store, and even from big box stores like Home Depot or Lowes.

It provides a unique look

Rural regions that have a lot of barns, silos, and other agricultural structures might be considered a more traditional look.

Disadvantages of Exposed Fastener Metal Roofing

Many opportunities for leaks

Drilling holes in your roof is not something you want to let anyone do. Exposed fastener metal roofing actually does require installers to drill many holes (for fasteners and screws) in the metal that is protecting your structure. This opens up the roof up to a myriad of problems, mainly: Water penetration and leaking. Leaking is a major problem with metal roofing, primarily because water can do a lot of damage in a short amount of time. Always be careful of how low of a slope and what type of underlayment you use on your roof.

Fastener issues

The integrity of the roofing structure can be put in the hands of the gasket and the exposed fasteners. This may lead to bigger issues such as:

Fastener withdrawal

It is inevitable that the metal roof will expand and contract over time. The amount of expansion and contraction of the roof can be limited by directly fastening the metal down to the structure without a clip, which can cause the fasteners to back out as the metal moves. There is a chance for water to get into one of the penetration points if the gasket is no longer touching the surface of the metal.

UV damage

The metal gasket is more susceptible to UV degradation than the metal itself. The amount of time that it takes a gasket to degrade from sun exposure varies depending on what material the gasket is made of. Maintenance on an exposed fastener metal roof is important because of the degradation of a fastener’s gasket.

Incorrect fastener installation

It is possible for water and air to leak into a structure when there are many penetration points and fasteners. Incorrect fastening can include overdriving, underdriving, and angling the fastening.

More frequent maintenance is required

If we compared to a standing seam metal roof, exposed fastener roofs need more frequent maintenance. This maintenance for the metal roof includes:

- Inspecting the surface of metal roof, looking for scratches, scuffs, chalking, fading, and flaking.

- Looking for any spots where the surface is chipping, cracking, or peeling.

- Checking to make sure all of the fasteners are still in good condition and that they are not backing out,

- loosening, rusting, or showing other signs of deterioration.

- Making sure all of the exterior foam closures are still in good condition and where it should be.

No weather-tight warranties are offered

Because of the many problems associated with putting many holes in a roof, t’s difficult for manufacturers to offer a warranty on their products. In fact, we don’t know of any companies that offer weather-tight warranties on their exposed fastener products.

No low pitched roofs

Every panel has many screw penetrations through its surface with exposed fastener systems. The standard for exposed fastening systems is a minimum 3/12 roof slope. When you have a roof that isn’t steep enough, you don’t want the water to pool on the roof, because the water is going to be forced into your building or home.

A less sleek approach

Most new buildings have a clean, modern look. That’s something an exposed fastener metal roof can’t offer. The heads of the fasteners are raised above the surface of the metal, giving this type of roof a bumpier and less sleek look.

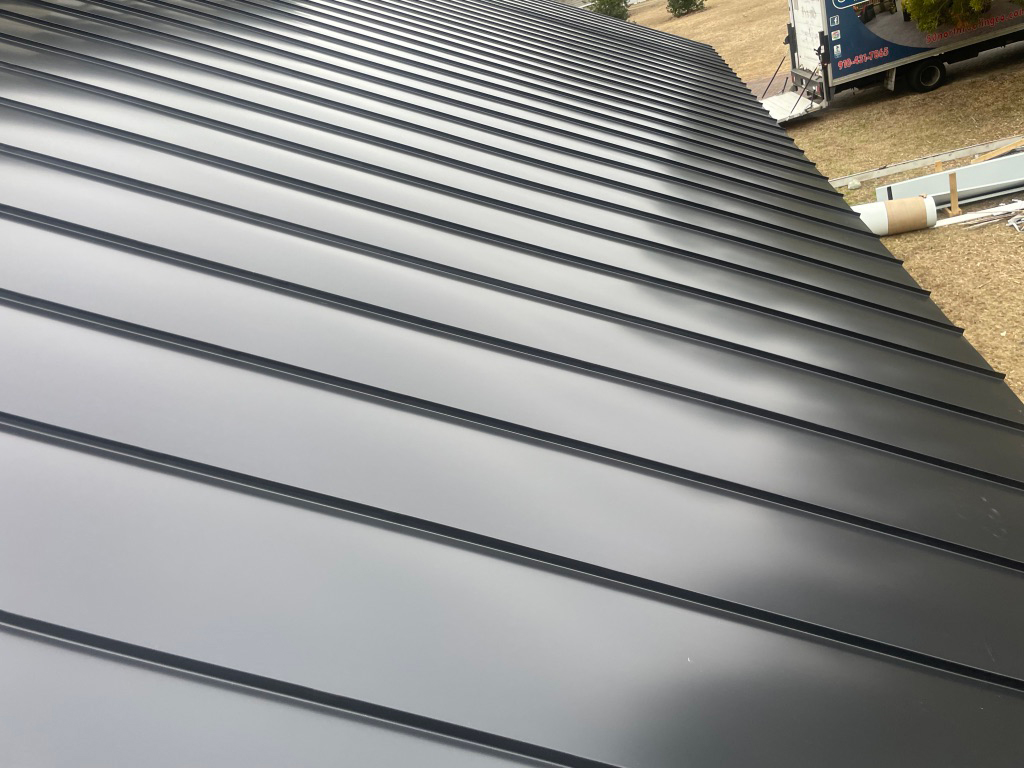

Standing Seam Metal Roofing

A standing seam metal roofing system is a concealed metal panel system with a broad, flat area between the seams. It is described as having raised seams, or vertical legs, that rise above the flat area. Standing seam systems can be installed with hidden fastenings, whether the panel is attached to the roof deck using a clip or directly fastened to the deck under the vertical seam. Standing seam is a quality system that is used on commercial and residential roofing projects.

The benefits of standing seam metal roofing

Concealed fasteners

One of the most significant benefits of standing seam metal roofing is that it doesn’t put holes in the panels protecting your building. Fasteners are not visible on the surface, which means they aren’t exposed to the elements that can cause a screw to wear or fail over time. Also, due to the fact that some people see the heads as unattractive, using a standing seam system is very common.

Warranties

The weather-tight warranties, which are offered by some the manufacturers of standing seam systems, are another safeguard of standing seam systems. The manufacturer claims to be responsible for remediating the issue if the metal roofing system fails during a specific period of time and weather conditions.

It is possible to allow thermal movement

You can run into problems, such as oil canning if you restrict the expansion and contraction of the metal panel. The panels in standing seam roofing systems can expand and contract better if they aren’t double pinned. This is also true if the metal can move with a clip and if it is a snap-lock system.

Longevity and lifespan

When compared to exposed fastener standing seam metal roofing lasts significantly longer and requires less maintenance. Regular maintenance to check for withdrawing, loose, or damaged fasteners on a standing seam system is not necessarily because the fasteners don’t penetrate the surface of the metal. Maintenance on a standing seam roof is still important. It is recommended to be performed by a professional contractor. Also, the lifespan and the appearance of your roof will be increased by the use of a PVDF paint system on standing seam metal roof systems.

Some systems are tested to the high standards

Standing seam metal roof systems are tested to the high standards set forth by industry leaders, including ASTM, UL, and FM Approvals. They’re becoming more and more popular, especially with commercial buildings in hurricane and high-wind zones. They typically adhere to testing standards for wind uplift, air leakage, water penetration, fire/combustion resistance, and impact resistance.

The look is sleek, conform, and modern

Because of its clean look, standing seam is becoming more and more popular in architectural applications. In addition to the sleek, straight lines offered by these panel systems, the metal can come in virtually any color, including custom colors, to match the structure.

Architectural freedom

One of the reasons why architects are specifying standing seam systems more often is that they can be used on many different planes and designs.

Energy-efficiency

Standing seam systems are usually made with roofing coils that have reflective paint and metal. These systems do an excellent job of reflecting the sun’s rays and keeping the associated heat out. Cool roofing can help the cooling system work more efficiently. A variety of ENERGY STAR® rated colors and finishes can be found.

Different options for material

Some people think that standing seam metal roofing is only available in Galvalume. There are painted aluminum, zinc, and copper that can be used for standing seam profiles. But, remember to look for and ensure that these alternatives are installed to local building codes as installation methods can vary from steel for these other materials.

There are various options for mounting

The option to mount items, such as solar panels, snow retention systems, swamp coolers, and other rooftop additions, without making any holes in the surface of the roof, is one of the best parts about standing seam.

Disadvantages of Standing Seam Metal Roofing

Higher Cost

One of the biggest drawbacks to standing seam roofing is that it is more expensive than other metal roofing types.

The are fewer qualified workers available

Because standing seam systems require careful craftsmanship, it is important to find a contractor who is qualified, skilled, and experienced in metal roof installation. Since standing seam installations may be considered too complicated or tedious, there are far fewer contractors who have a proven track record and relevant experience to choose from.

The installation process can take a longer time

Fastening an exposed fastener system to the roof deck can be relatively simple. You just nail or screw it down. Standing seam metal roofs are much more complicated than gable metal roofs and can include:

- Forming the panels using portable roll forming or buying from regional manufacturers.

- Correctly spacing the clips on the panel legs and fastening each one down for snap-lock systems.

- Aligning the panels and snapping the legs together for mechanically seamed systems.

- Cutting all the necessary “Z” flashing for details, roof penetrations and ridge cap…

Not for use on a flat roof

It’s not a good idea for buildings or homes that have a roof below a 1/12 pitch to have standing seam systems. These flatter pitches don’t allow water to adequately drain, which could lead to premature degradation, color changes, and the overall failure of the panel system. It is recommended that snap-lock systems be installed above a 3/12 pitch.

It is more difficult to fix or replace

If there is damage to one panel or a smaller section of the roof, it can be difficult to replace because each panel must be separated. This process can be difficult for mechanically seamed systems, as each panel will need to be un-seamed and potentially, more than one panel needs to be removed.

Which metal roof style is better for you?

The budget is the most important thing to keep in mind when choosing between standing seam and exposed fastener metal roofing.

Choose standing seam if:

You’re willing to spend a little more money on your roof if it means you can afford a little extra.

Choose exposed fastener if:

You want to pay a lower price and save some money. If you want to hire a business to perform the maintenance on your roof, you need to know how much you want to do and how often.

Choose standing seam if:

You don’t want to perform maintenance or hire someone to perform maintenance on fasteners, but maybe twice a year.

Choose exposed fastener if:

If you’re okay with performing maintenance on it, twice per year is plenty. If you want to perform maintenance yourself, a good rule of thumb is once every six months.

The slope and pitch of the roof

The pitch of a roof is the most important factor when choosing between the two systems, as it can cause a failure and damage if it does not work well with the profile.

Choose standing seam if: If your roof pitch is at least 3/12 (Snap-Lock)

Choose exposed fastener if: If your roof pitch is at least 3/12

Choose neither if: There is a flat roof on your house. Flat roofing structures are not recommended to have metal roofing.

Who is doing the roof work?

Knowing how you want the roof installed on your property is one way to determine the type of roof you want. If you want to hire a qualified and skilled metal roofing contractor with standing seam metal roof installation experience who has their own roll formers, seamers, and other required tools, you need to choose standing seam. If you want to do the installation yourself, or you want to hire a less expensive contractor with experience installing exposed fastener systems, you could choose exposed fastener metal.

The roofing structure you have

There are some common uses for standing seam or exposed metal roofing on a building or home. Residential structures can use either system depending on performance and preference. If your building is commercial, architectural or residential, choose standing seam. If your building is agricultural, structural, residential, or open-framed, you could choose exposed fastening.

The look that you would like

When it’s complete, how you envision the building, specifically the roof, is a factor to remember. If you want a sleek, clean, and more modern look, choose standing seam. If you don’t mind the visible fastener heads, choose exposed fastener.

Warranty

Make sure you know if you need or don’t need a weather-tight warranty, because it’s important for some property owners and unimportant to others. If you want more warranty options, you need to choose standing seam. If you don’t mind not having a weather-tight warranty, you can choose exposed fastening.

Which metal roofing type is best for you?

It’s up to you. If you know what you’re looking for and expecting when you buy the roof, you’ll be better prepared to make the right decision. Standing seam metal roofing has a sleek modern look, weather-tight warranty options, space for thermal movement, and no panel penetrations. A traditional look, a roof that performs well, and a lower price point are some of the benefits of exposed fastener metal roofing. We are here to answer your questions and provide you with peace-of-mind as you go through choosing the right metal roofing type for your home or business.